Abstract:

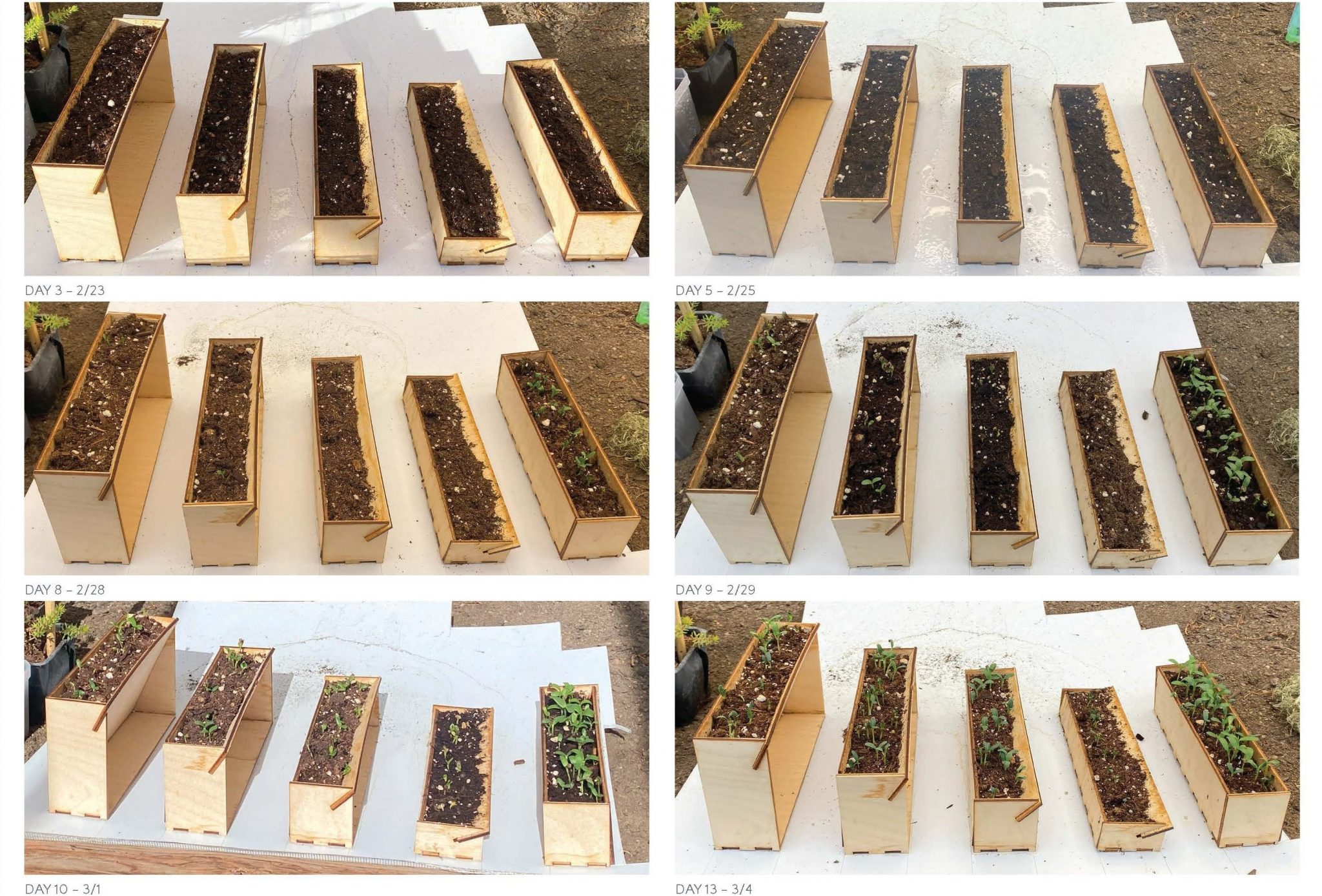

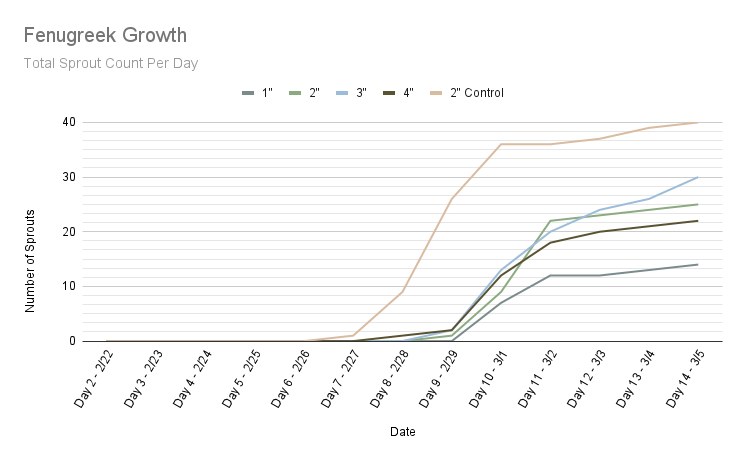

Sedum has been a favorite green roof species across the globe because of its resilient nature and its wide range of subspecies. But this species has not been implemented in a living wall, because of their weight and the low volume creeping varieties. To address these challenges, I propose a system which adapts concrete masonry units (aka. CMU or cinder blocks) by the addition of a cast concrete planter. Concrete is porous which aids in draining soil. And angled planters would allow for soil depth without overlapping the vegetation. Before creating the final prototype, to investigate the minimum soil depth required test models will be planted with Fenugreek seeds, an alternative fast-growing species. The outcome of the soil depth testing was that the 2” control and the 4” and 3” test models were the most successful, producing the highest number of sprouts. Therefore, the final prototype was designed and successfully fabricated with an overall depth of 4 ½” and a width of 2 ½”. This investigation could expand the use cases for Sedum, a versatile and accessible species, bringing air purifying and sound dampening benefits to the interior. The use of CMU as the base structure for this system means it will be easily replicable and offers an opportunity for the adaptation of existing structures or for the reuse of existing materials because of the additive construction methods. Additionally, the use of 3D printed molds for casting is a more accessible alternative to the popular innovation of 3D concrete and ceramics extrusions.

Soil Depth Testing:

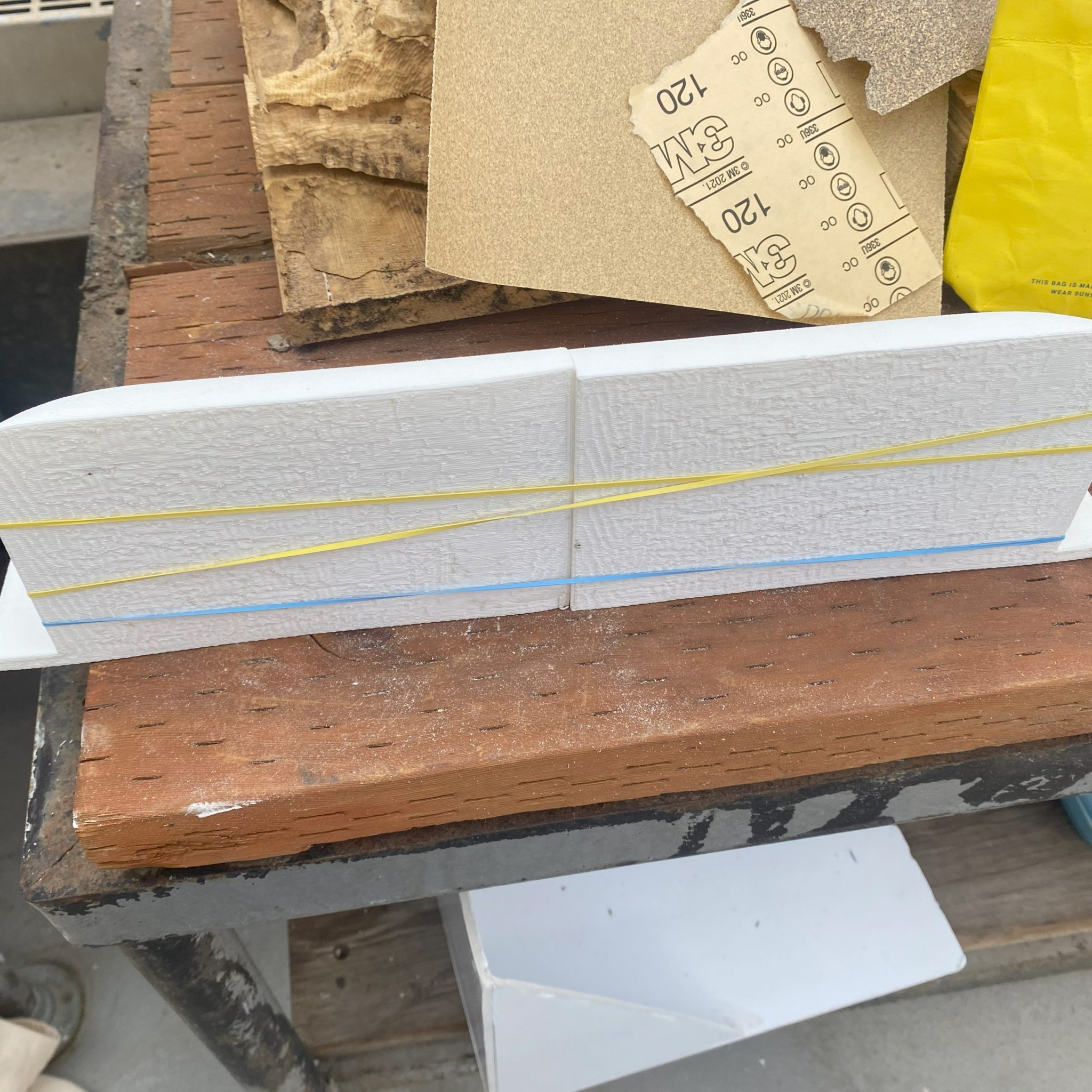

Fabrication Process:

Mold before sanding

Mold after sanding

Assembling halves of mold

Assembling full mold

Casting mold

Removing cast

Attaching cast to CMU

Planting Sedum

Exploded Axonometric:

Conclusion:

Ultimately, although the soil depth testing did not produce results indicating the possibility of using a soil depth of less than 3”, this project was successful in investigating new methods of construction for possible green walls. I believe the results of the soil depth testing are not entirely conclusive, given all soil depths successfully produced sprouts and most of the testing period was taken by the germination of the Fenugreek seeds. Although the germination and early development is an indication of the plant’s survival, I believe that a trial with a longer observation period of plants with a developed root system might reveal different results as they would require less watering. Overall, the success of plaster casting using a 3D printed mold shows promise for the ability to also cast concrete using the same methods. This technique could be used in numerous applications, making use of common fabrication tools and design techniques to achieve equivalent results to 3D printing ceramic or concrete extrusions.

See this studio featured on the UO Architecture & Environment and UO College of Design Instagrams ->